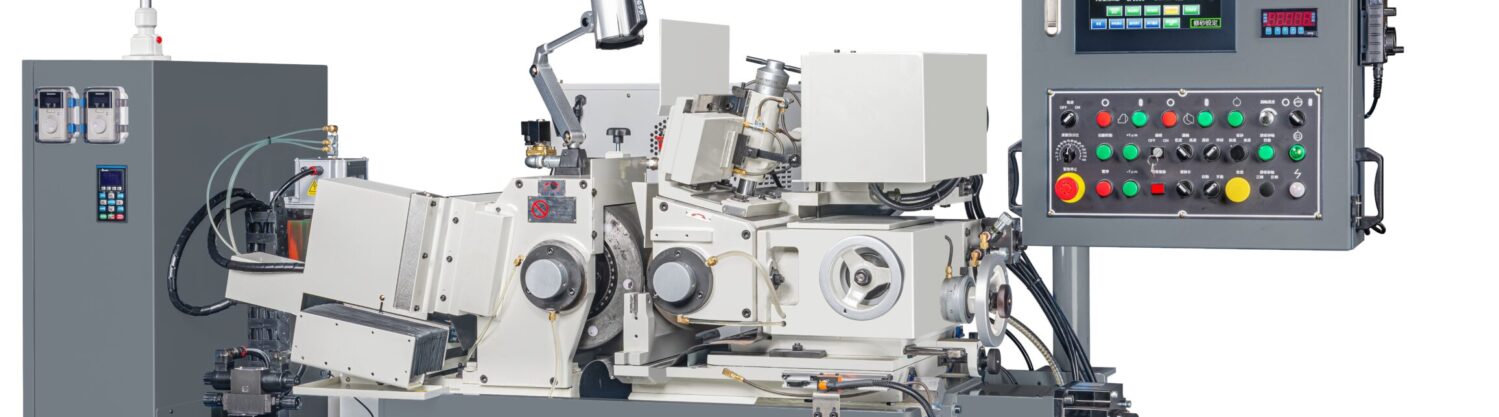

Centerless Grinding Machine-NC Advanced type

Centerless Grinder NC Advanced type

- ✅ High Precision – Achieves ≤ 0.002 mm accuracy consistently after dressing.

✅ Mitsubishi Q-Series – Ensures reliable, high-performance automation.

✅ Pro-Face 10″ Touch screen Interface – User-friendly operation with step-by-step guidance.

✅ Closed-Loop Linear Scale Compatibility – achieve 0.0002 mm without back lash

✅ Smart Memory Function – Automatically retains processing points; no need to reset zero after power cycles.

✅ Stable Precision Without External Feedback – Maintains < 0.002 mm tolerance post-dressing, - ✅ Easy for new technician.

Together with Loop linear scale

High feeding accuracy up to 0.0002mm ignoring the backlash