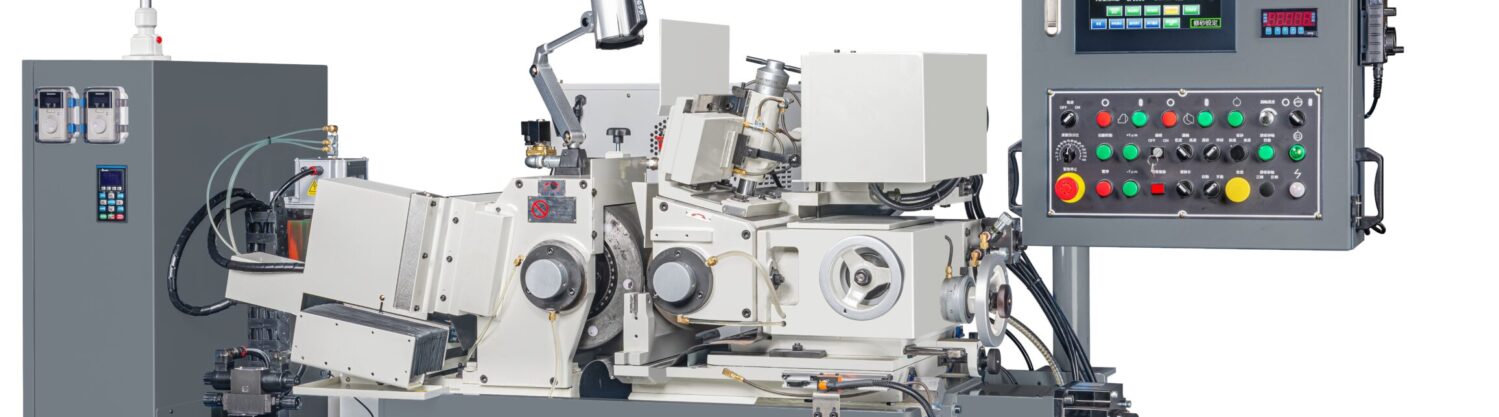

Centerless Automation

Centerless Grinding Automation: Designed Around Your Part & Process

Centerless grinding automation is mainly determined by the workpiece geometry, grinding method, tolerance target, and surface requirements. In general, centerless grinding can be categorized into:

- Infeed (Plunge) Grinding Automation: best for stepped parts, short parts, or components requiring positioning.

- 無心研磨通過式自動化: continuous feeding for long parts and high-volume production.

Once the proper machine type and grinding method are selected, the next key question is:

How to load and feed the workpiece into the grinding zone consistently and safely.

Why Centerless Automation Is More Challenging

Unlike center-type grinding, centerless grinding has no center reference. During dressing or compensation, the grinding position may shift, and the automation system must ensure:

- The inlet position can be adjusted accordingly

- The workpiece maintains proper support and guidance

- Risks such as jamming, collision, size drift, and scratches are minimized

This is also why many general automation suppliers struggle to apply standard modules to centerless grinders.

To improve flexibility and reliability, our designs typically integrate a PLC-based control system, enabling smoother coordination between feeding, dressing interlocks, compensation, and cycle timing.