Infeed Centerless Grinding – Puncher

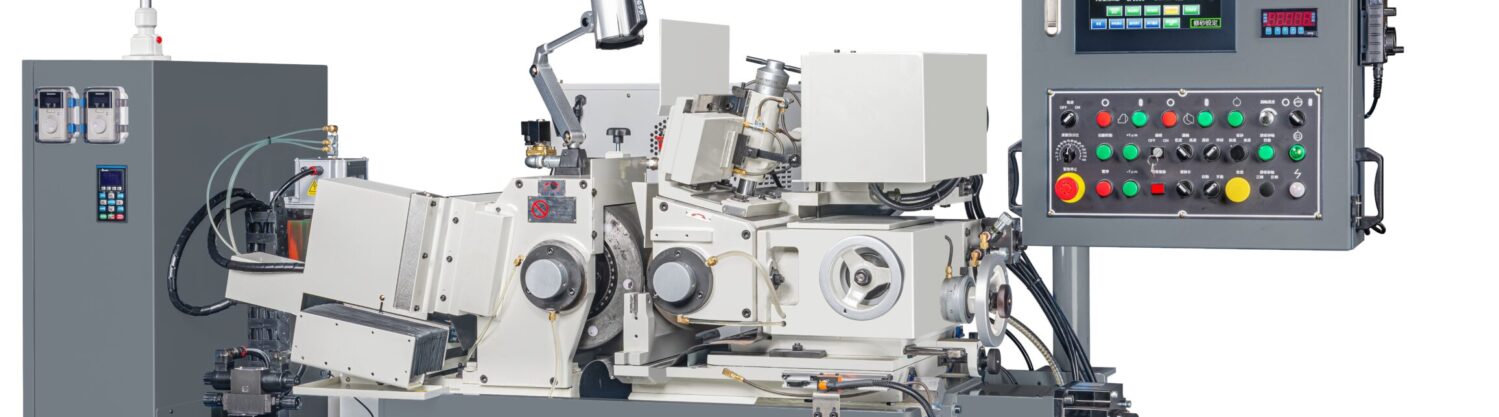

S-12NC1 Centerless Grinding Machine + Infeed Grinding Automation (Two-Stage Pneumatic Feeding System)

Automated Infeed Grinding System Overview

The S-12NC1 centerless grinder is equipped with an infeed grinding automation system featuring a two-stage pneumatic feeding mechanism.

This design ensures stable loading and precise control during the grinding of short or small workpieces, achieving both high accuracy and production efficiency.

Workpieces are automatically transferred from the flat conveyor into the V-shaped guide rail, which then delivers them precisely to the grinding position.

During the grinding cycle, the V-block’s backward delay timing can be adjusted to maintain stable positioning until the process is complete.

After grinding, the automatic unloading device quickly ejects the finished parts into the discharge chute, enabling a fully automated production line.

💡 Machine Features & Advantages

-

Model Configuration: Centerless Grinder S-12NC1 + Infeed Grinding Automation System

-

Two-Stage Pneumatic Feeding: Dual-cylinder feed design provides smooth entry and high positional repeatability

-

V-Block Stop Function: Prevents short workpieces from bouncing or reversing due to air pressure during grinding

-

Automatic Unloading Mechanism: Rapid part removal for improved cycle efficiency

-

High-Precision Grinding Performance:

-

End-to-end size variation: within ±0.002 mm

-

Stock removal: within 0.15 mm

-

Dimensional accuracy: within 0.01 mm

-

Up to 50 pcs per wheel-dressing cycle

-