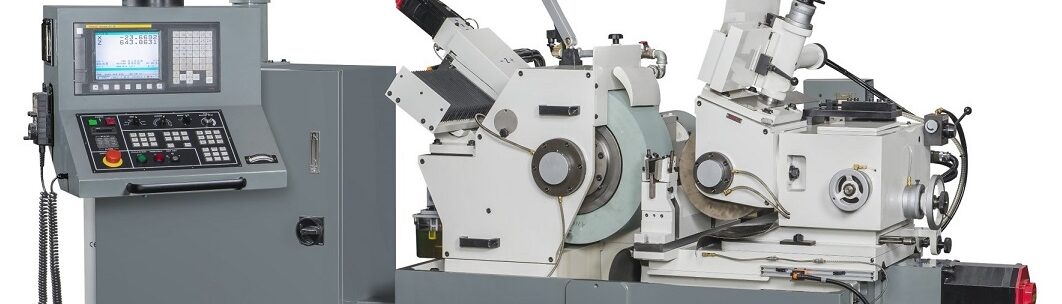

Infeed Centerless Grinding –S-18S Three-Step Diameter Grinding for Motorcycle Parts

Infeed Centerless Grinding –S-18S Three-Step Diameter Grinding for Motorcycle Parts

The STP S-18 Centerless Grinder is equipped with a hydraulic infeed system and a dual-clamp automatic loading/unloading mechanism.

It enables high-precision multi-diameter plunge grinding for motorcycle parts and other precision shafts such as bushings, fan shafts, and transmission shafts.

-

Dual-Clamp Automatic Loading/Unloading System:

The dual grippers move synchronously during the infeed motion, ensuring stable and smooth loading/unloading cycles. This synchronized motion enhances process stability and automation efficiency. -

Manual Loading Area with Fool-Proof Design:

The loading zone is manually operated but equipped with a mechanical anti-error design to prevent mis-orientation or mixing of similar parts, ensuring consistent production quality. -

Automatic Discharge System:

After grinding, the rear clamp automatically transfers the finished workpiece to a flat-belt conveyor, completing a fully automated process loop.

Application

This system can complete three different diameters in a single infeed operation, making it ideal for multi-step precision shafts such as motorcycle parts, copper shafts, steel shafts, motor shafts, and fan shafts.

-

Workpiece Diameters: Ø12 mm / Ø16 mm / Ø20 mm

-

Concentricity (Between Centers): ≤ 0.02 mm

-

Three-Step Grinding Accuracy: ≤ 0.003 mm

-

Overall Process Control: Concentricity maintained within 0.02 mm