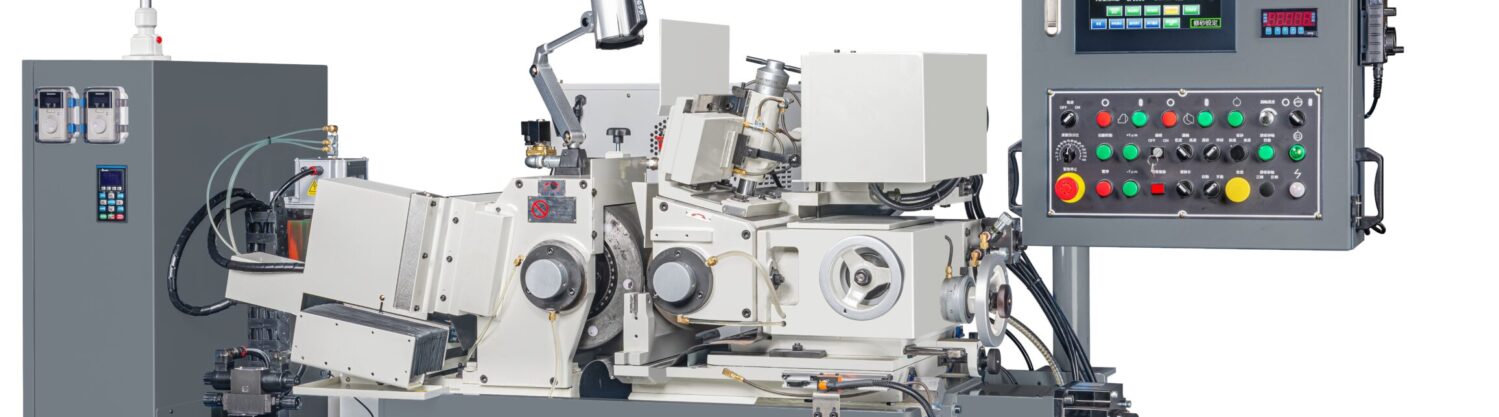

Infeed Centerless Grinding Automation for Bicycle Y-Fork (Model 18NC6)

The S-18NC6 infeed centerless grinding automation system is specially designed for carbon-fiber and glass-fiber Y-figure bicycle parts such as forks and handles. This customized automation concept enables fully unattended operation, allowing the machine to complete all programmed grinding cycles automatically — ideal for composite materials that require precision, consistency, and surface protection.

Key Features

-

Model S-18NC3 + Auto Dressing and Infeeding System

Integrated with automatic wheel dressing and infeed control, ensuring consistent geometry and smooth surface finish for composite bicycle components. -

3-Axis Robotic Loading / Unloading

A high-speed three-axis manipulator provides precise positioning and stable loading for asymmetric Y-shape parts. -

Smart Dialogue Interface

The user-friendly dialogue programming allows quick setup for different workpiece shapes and sizes without complex parameter input. -

Special Pressing and Holding Devices

Designed to secure Y-shaped workpieces with a heavier head and lighter body, maintaining perfect balance and minimizing vibration during grinding. -

Stop Device with Length Control

A stop-and-hold mechanism accurately controls grinding length and prevents part movement, ensuring micron-level repeatability.

Applications

-

Material: Carbon fiber / Glass fiber composites

-

Workpiece: Bicycle Y-forks, handles, and other composite structural parts

-

Process: Precision infeed centerless grinding for light-weight, high-strength components