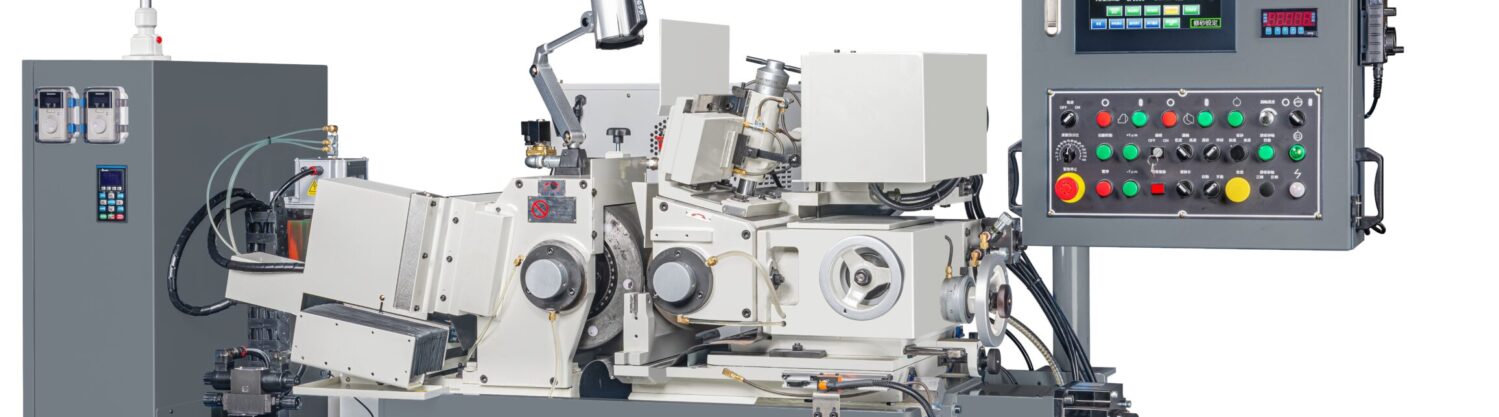

Centerless Thrufeed Grinding Adjusting

Step 1. Choosing the right blade. Fro 3-12, the principle is T small than workpiece diameter bigher than 1/2 diameter. Then make sure blade is parallel to the Grinding wheel.

Step 1. Calculate the central height.

H (the measuring height) minus r (the half of the workpiece diamenter) = central height. The central height should be bigger than the standard of each type of machine. Basically it should be higher around 1/4 of the workpiece. if the number is smaller than one, we would like to say one.

Step 3.: Adjusting the R.W Swirling angle to decide the grinding volumn. if yon wanna grind 0.15mm. The correct drawing should be toughing at bottom . Then infeeding 0.15mm, you touch the entrance. where is the entrance point is decided on your regulating dressing and the tilt angle.

Adjust the Guide. If your grinding volumn is 0.15mm. You have to adjust back guide from bottom point. And then gradually adjust the front guide every infeeding 0.02mm till the entrance point (decided by R.W dressing angle and tilt angle.)

STEP 4-1. Finding bottom toughing point to adjust the back guide

STEP 4. 2 Gradually adjust the front guide every infeeding 0.02mm till the entrance point (decided by R.W dressing angle and tilt angle.)

Adjusting Issue: when the size wrong and regular

Adjusting Issue: The middle size is smaller

How to solve 1.Try to make is head or bottom smaller . 2.Then adjust another one side