Infeed Grinding Automation

How to choose Infeed Grinding Automation, the follwing shows you the guide to draw your own machine. According to the figure, material, reservation and precision of the part, we will help you design a fantastic automation. Let’s talk about it in detail and separately.

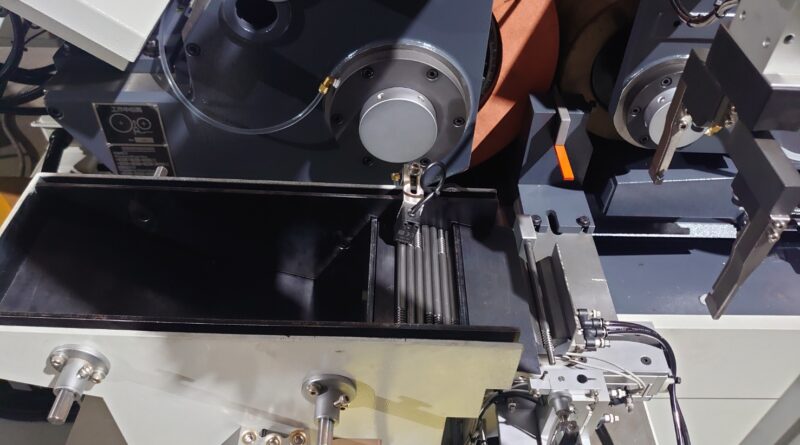

- Figure: the clamping way, dressing way and the grinding wheel style.

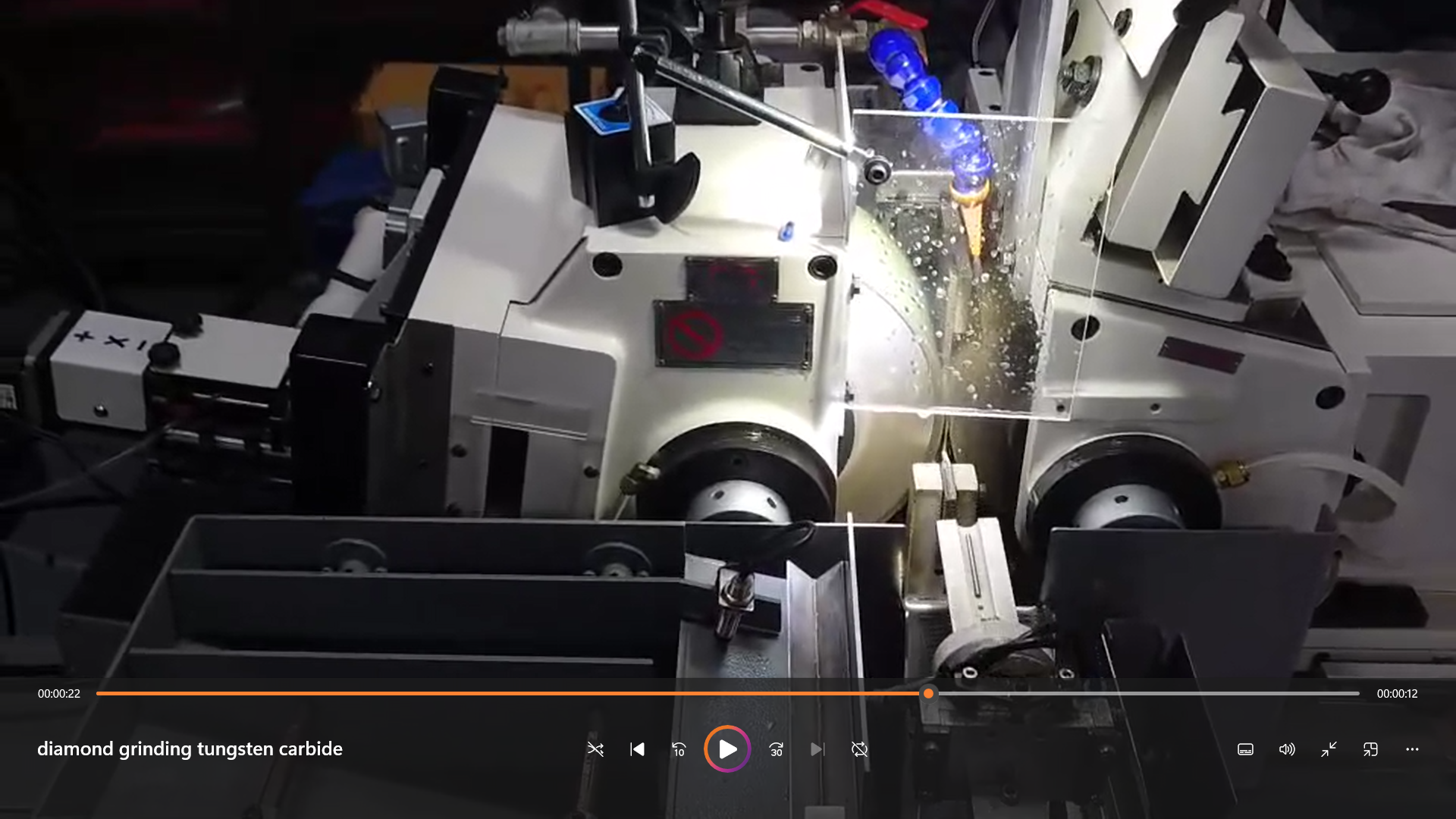

- Material: the loading way, dressing way and the grinding wheel material: Ex: Tungsten carbide: we use diamond wheel to grind it and using rotating device dress the wheel.

- Reservation: decides the axis driven power and dressing frequency.

- Precision: decides and the clamping way, dressing way, driven power. Ex: good roundnessneeds dressing and infeeding slowly.

- Also, grinding wheel and coolant are important.

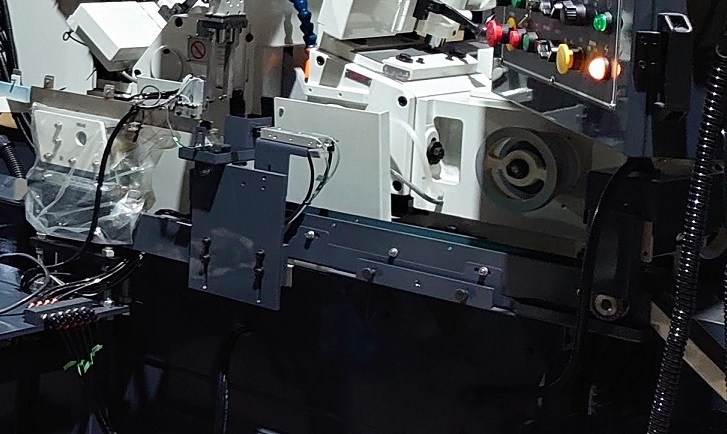

Alought, the Infeed Centerless Grinding Automation is very customised. but during years’ effort, we have try to make it in serval combinations. Then we willl use the real case to introduce it. Here, we seperate it into three aspects to show you. 1. preparing loading system 2. delivering device into the grinding place 3. unloading device.

- Preaparing loading System (A)

- Vibration Hopper

- Ladder type

- Lifting chosing tyep

- Delivering device into the grinding place (B)

- Two clamping arch way

- One clamping arch way

- V delivery two steps

- Unloading way. (C)

- Belt type unloading (front / middle / back)

- uploading axis back

- penumatic assisting unloading