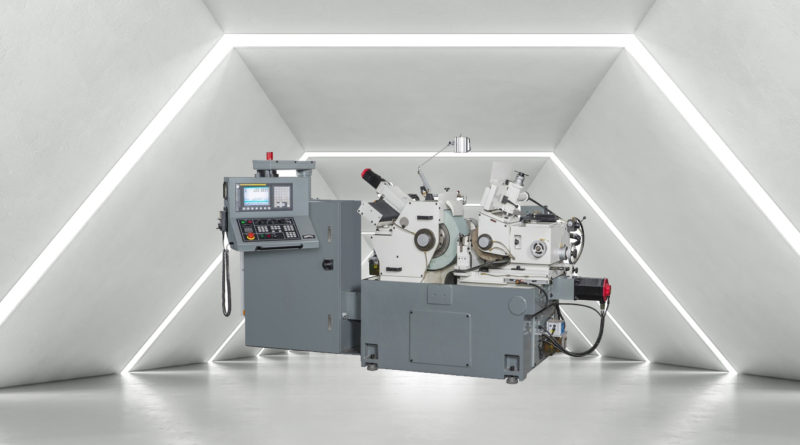

CNC Centerless Grinding Machine

CNC Centerless Grinding Machine is also called numerical programmable system. The mainly controllers Fanuc Oi-TF plus and Misubishi M80V are used in S-TYP. Based on the workpiece, you can edit the program to decide your dressing figure, loading and unloading procedures. Each axis resolution is belwo 0.001mm. This would be good for sophisticated engineer to do complicated work.

The big difference beteen CNC and NC type it that NC type is made for unique type of workpiece for mass production. S-TYPE will dsigne the machine structure with automaton presented through the dialogue screen. It is very customised, so we will have a good dicussion before making this machine.

On the other hand, the CNC Centerless Grinding Machine customer knows how to design the necessary accessories like blade, loading and unloading system, dressing figure, stopper ets. Such an expert, when changing workpiece, using the controller to combine these factors.

PS: When choosing CNC type, the engineer basically know to how to edit the program and centerless grinding implication. Otherwise, NC type would be strongly recommended.

Specification

| Model | Unit | S-12CNC | S-18CNC | S-1812CNC | S-20CNC |

| Advanced CNC series | FANUC | ||||

| Grinding Range(dia.) | mm | 1-30 | 2-50 | 2-60 | 2-60 |

| Grinding wheel size(dia.*W*H) | mm | 305*150*120 | 455*205*228.6 | 455*305*228.6 | 510*205*254/304.8 |

| Regulating wheel size(dia.*W*H) | mm | 205*150*90 | 255*205*111.2 | 255*305*111.2 | 305*205*127 |

| Spindle speed | |||||

| Grinding wheel speed | R.P.M | 1900 | 1500 | 1500 | 1350 |

| Regulating wheel speed (Servo) | R.P.M | 0-300 | 0-300 | 0-300 | 0-300 |

| Main power motor | |||||

| Grinding wheel Motor | HP | 10 | 15 | 20 | 20 |

| Regulating wheel Motor(Delta Servo) | K.w. | 2 | 3 | 5 | 5 |

| Hydraulic Pump motor | HP | 1 | 1 | 1 | 1 |

| Coolant Pump motor | HP | 1/8 | 1/4 | 1/4 | 1/4 |

| Standard infeeding Manual part | |||||

| Upper slide feed graduation | mm | 0.05 | 0.05 | 0.05 | 0.05 |

| Upper slide micro feed graduation | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Lower slide feed graduation | mm | 0.05 | 0.05 | 0.05 | 0.05 |

| Lower slide micro feed graduation | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Dressing device graduation | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Servo Feeding | |||||

| Upper slide feed graduation | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Upper slide servo motor | K.w. | 1 | 2 | 2 | 2 |

| Lower slide feed graduation | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Lower slide servo motor | K.w. | 2 | 3 | 3 | 3 |

| Dressing device graduation | mm | 0.001 | 0.001 | 0.001 | 0.001 |

| Dressing servo motor | K.w. | 0.75 | 0.75 | 0.75 | 0.75 |

| Regulating wheel angle | |||||

| Regulating wheel tile angle | deg. | 5 / -3 | 5 / -3 | 5 / -3 | 5 / -3 |

| Regulating wheel swivel angle | deg. | ±5 | ±5 | ±5 | ±5 |

| Regulating wheel dressing angle | deg. | ±5 | ±5 | ±5 | ±5 |

| Machine layout | |||||

| Machine Dimensions | mm | 1900*1550*1420 | 2450*2050*1600 | 2450*2050*1600 | 2650*2150*1600 |

| Machine Weight | kgs | 1550 | 3200 | 3200 | 3500 |